Sonja Salmon is a huge admirer of cellulose, and which is why she wishes to demolish it. “I appreciate cellulose,” she says. “I’m ripping cellulose apart mainly because I enjoy it.”

She’s also pulling it aside for the reason that the polymer, which is uncovered by natural means in wooden and cotton, accounts for one-quarter of all the fibres used in textile manufacturing. That suggests any energy to recycle clothing and fabric to hold them part of the round financial system for as lengthy as possible has to include techniques to deal with all that cellulose.

Salmon, a polymer scientist at Wilson Faculty of Textiles, North Carolina Condition University in Raleigh, is performing on breaking down the cellulose from discarded textiles and reusing it. A lot of clothes fabrics are a mix of 50 percent polyester and 50 {5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} cotton—individual fibres of cotton and polyester are twisted tightly close to a person a different, generating a yarn that is then woven or knitted into a garment. Having that composition apart mechanically is demanding, so instead Salmon treats it with cellulases, a team of enzymes that break up the cellulose. “We can chew it up into tiny adequate molecules and fragments that it will basically tumble out of the rest of the cloth framework,” Salmon claims.

Her emphasis is on characterizing the substance that arrives out of the breakdown approach and doing the job out what it may well most effective be made use of for. For case in point, the enzymes break down the cellulose into glucose, which could be utilized as a feedstock for making biofuel. They also depart driving tiny chunks of cotton fibre that could give lightweight reinforcement for concrete. “Even while the cotton fibre will no extended be extended ample to instantly spin it again into a yarn, we think the substance has value,” Salmon claims.

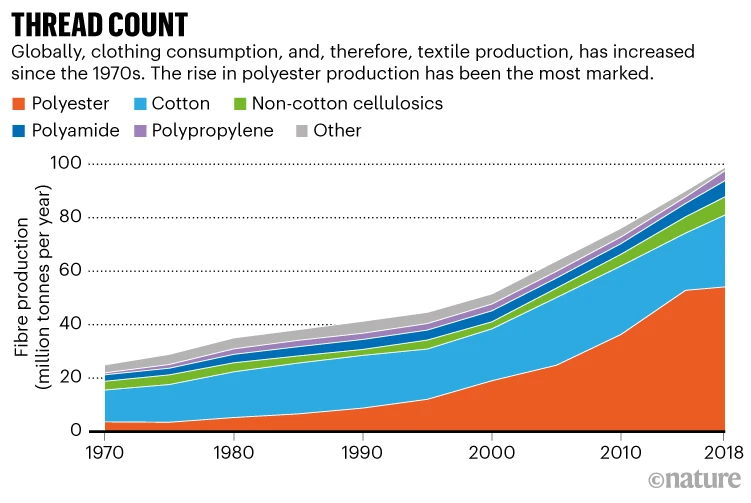

This way of contemplating is a huge transform from how previous outfits and textiles, these types of as upholstery fabrics and carpeting, are now managed. Globally, only 13{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of the materials that goes into making clothing is recycled, in accordance to the Ellen MacArthur Basis, an corporation in Cowes, British isles, that encourages the circular economic system. Most textile waste—an approximated 92 million tonnes from the trend market alone—produced each and every calendar year winds up buried or incinerated. “We toss things away into landfill and we’re managing it like garbage,” Salmon states. “We’re not searching on it as a thing that is actually a raw content that could be reused.” The US Environmental Defense Agency believed that, in the United States in 2018, the ordinary human being threw away 47 kilograms of textiles. About 3-quarters of that— 36 kg—is outfits and footwear, while the relaxation is mainly towels, bedding, household furniture fabrics and carpets. In the meantime, means are expended to build virgin substance (see ‘Thread count’)—water and land to grow a lot more cotton, and petroleum to make a lot more polyesters (see ‘Recovering polyester’).

To counter all that waste, scientists and commence-up organizations are creating methods to recover and reuse the product. Very similar to Salmon, a great deal of their aim is on chemical recycling, in which the substance is damaged down into its setting up blocks and utilized to build new products, which includes fibres that can be woven into new clothes. The problems lie in establishing the processes for these types of treatment method. They have to be useful, but they also have to be at minimum as price-helpful as just building new fibres.

Spinning new threads

In addition to the pure cellulose fibres from cotton, some textiles contain human-produced cellulosic fibres. These fibres are derived from wooden-pulp cellulose and can be used to make elements these kinds of as viscose (rayon) and a very similar product termed lyocell. Cellulosic fibres make up about 6{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of all textile fibres developed, according to the Textile Trade in Lamesa, Texas—a non-gain organization that promotes environmentally welcoming products.

A variation on the lyocell-manufacturing course of action is getting used to the textile-squander trouble by Evrnu, a commence-up in Seattle, Washington. Just one main alter the business has designed to the approach is it employs discarded textiles, rather of wooden, as the source of its cellulose. Its also tweaked the method to create a fibre that the firm’s co-founder and president Christopher Stanev states is exceptional to equally other cellulosics and to cotton, and that can be recycled much more occasions. “We can make substantially stronger fibre making use of cotton than the just one coming from wooden pulp,” states Stanev, a textile engineer.

In the same way as the conventional lyocell procedure, the raw material is dealt with with N-methylmorpholine N-oxide (NMMO), an natural compound that dissolves cellulose. This produces a thick pulp that is then filtered. At this stage, the typical system would entail the cellulose currently being extruded via a system termed a spinneret—first into air, and then into a coagulation tub of primarily h2o in which the substance solidifies into fibre. Evrnu, nonetheless, turns the cellulose molecules into liquid crystals before they are extruded, permitting them to align with each other and produce a additional crystalline fibre structure.

Recovering Polyester

Cellulose isn’t the only polymer scientists want to reuse—they also have polyester in their sights

Polyester is a generic phrase for a range of polymers derived from petroleum, but it largely refers to polyethylene terephthalate (PET). Globally, PET polyester tends to make up all over half of all fibre in all textiles. Cotton contains yet another a person-quarter and the relaxation consists of other plant-based fibres, these kinds of as linen and hemp animal products and solutions, this sort of as wool and alpaca other synthetics, like acrylic and nylon and human-manufactured cellulosic fibres.

Like cotton, PET polyester can be spun into new fibres, but the re-spun fibres come to be shorter and weaker with repeated cycles. As opposed to cotton, having said that, the polymer could be damaged down into the more simple molecules that make it up and these monomers could then be reconstituted into new polymers. Starting up with waste PET, Sonja Salmon, a polymer scientist at North Carolina State University in Raleigh, states, it’s possible to produce what is effectively a virgin material—one that is indistinguishable from PET made from petroleum. PET is exceptionally secure, on the other hand, so decreasing it to monomers is challenging.

Some scientists are establishing enzymes that might be able to deal with these molecules. In 2016, a crew found out a bacterium that could break down PET (S. Yoshida et al. Science 351, 1196–1199 2016), and experts have considering the fact that made other enzymes to degrade it (J. Egan & S. Salmon SN Appl. Sci. 4, 22 2022). Christopher Stanev, co-founder of Evrnu in Seattle, Washington, claims together with its key focus of breaking down cellulose, the start out-up is also doing work on procedures to crack down PET and polyurethane, and to separate polyester–cotton blends.

“By carrying out that and owning rather a crystalline group, you can enhance the strength and you can also engineer the efficiency of this fibre,” Stanev suggests. He says the fibre is about 20{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} stronger than regular lyocell, which alone is more robust than cotton.

That quality interprets into a longer life time for a fabric manufactured from the fibre, as well as a fibre that can be reconstituted quite a few instances. Each individual time the molecules are operate through the recycling approach, they turn out to be shorter and thinner. But for the reason that they start out more robust, Stanev states, the similar substance need to be able to be reconstituted at minimum 5 times in advance of it turns into weaker than virgin cotton fibre some assessments in the company’s laboratory display that the material can be recycled up to ten periods. Which is more than is achievable for paper, which can be recycled 5–7 moments prior to the fibres grow to be much too short to make a viable new item.

Evrnu is functioning a pilot task at spouse organizations in Germany and somewhere else in the United States to demonstrate that its procedure can make material. It hopes that a more substantial textile corporation will then want to license the technological know-how. For now, it is applying NMMO mainly because the compound is easily out there, but Stanev hopes to inevitably change to an ionic liquid—a salt that is liquid down below 100 °C—which is more chemically secure than NMMO and far more tolerant of contaminants. The company has not yet optimized any these types of liquids for the creation process.

A Finnish firm, having said that, is doing the job with an ionic liquid created by 1 of its founders, physical chemist Herbert Sixta at Aalto University in Espoo, Finland. The liquid employed by Ioncell—the name of equally the organization and the process—is a superbase, a hugely alkaline compound that breaks the hydrogen bonds in the cellulose molecules. In the same way as when using NMMO, that process results in a pulp that can be fed by way of a spinneret to make a new cellulose fibre. NMMO tends to be unstable and demands the addition of buffer methods, but the ionic liquid does not. Sixta states his ionic liquid is also completely recyclable, building the course of action environmentally pleasant as well as making fibres with much better mechanical properties than cotton.

The Ioncell procedure can use wood pulp, which Sixta suggests counts as aspect of a round economy simply because the raw substance will come from Finland’s sustainable forests—these are managed in these types of a way that growth outpaces the volume eliminated. “Our university has a substantial team in textile design, so we can treat wooden, create pulp, transform it to fibres, change it to yarns, change it to materials, layout clothes, and present the garments in fashion exhibits,” Sixta states. The system can also accept textile squander, turning aged garments into new garments. Ioncell has developed a pilot plant, with the target of evaluating how effectively its course of action is effective in the true environment in about two a long time.

A make any difference of cost

Even though technical difficulties abound, the major barrier to prevalent textile recycling may well be financial, claims components engineer Youjiang Wang at the Ga Institute of Know-how in Atlanta. “Most of the components are not that worthwhile,” Wang states. It is so inexpensive to create polyester, cotton and other fabrics that there’s little revenue margin except if the recycling procedures are incredibly low-cost.

There’s also a absence of infrastructure for collecting and sorting employed textiles, outside of a couple of private apparel-donation groups. And the intricate mixture of components in a piece of clothing—not just various all-natural and synthetic fibres, but also dyes and chemical coatings, buttons and zips, and any non-woven additions these as leather or latex—must be divided for particular person components to be processed.

Policymakers should contemplate recycling that turns employed outfits not into new dresses but into other useful—if reduce value—products, Wang argues. Fibres could possibly be shredded for use as soil stabilizers, for instance, or cellulose damaged down into glucose that can be turned into fuel. Even burning polyester for energy is preferable to pulling much more petroleum out of the ground to produce power. “That does not audio very significant tech, but overall, you do get substantial benefit from that,” Wang claims.

The round economic climate must be seen as a way to minimize as significantly as possible the generation of virgin product when other solutions can be reused, Wang states. “If you definitely want to make recycling improved for the setting, not just for the sake of publicity, then we require to acquire more systems so that you can use as a great deal of what you gather as attainable,” he suggests. “That would make the general circle additional round.”

This report is part of Character Outlook: Round Economic climate, an editorially unbiased nutritional supplement generated with fiscal support from Google. About this articles.