North Carolina Condition University experts uncovered a way to separate blended cotton and polyester cloth working with enzymes, which are nature’s applications for dashing up chemical reactions. They hope their outcomes will consequence in a far more successful strategy of recycling the fabric’s part supplies, cutting down textile squander.

Even so, they found out that if the blended cloth was dyed or taken care of with chemical compounds that significantly increased wrinkle resistance, the process demanded much more steps.

We can independent all of the cotton out of a cotton-polyester blend, that means now we have clean polyester that can be recycled. In a landfill, the polyester is not likely to degrade, and the cotton could possibly consider many months or far more to break down. Making use of our strategy, we can separate the cotton from polyester in less than 48 hrs.

Sonja Salmon, Research Corresponding Writer and Associate Professor, Textile Engineering, Chemistry and Science, North Carolina State University

According to the Environmental Security Company, people in the United States toss somewhere around 11 million tons of textile waste into landfills every yr. The investigators wished to discover a way to individual the cotton from the polyester so that just about every component materials could be recycled.

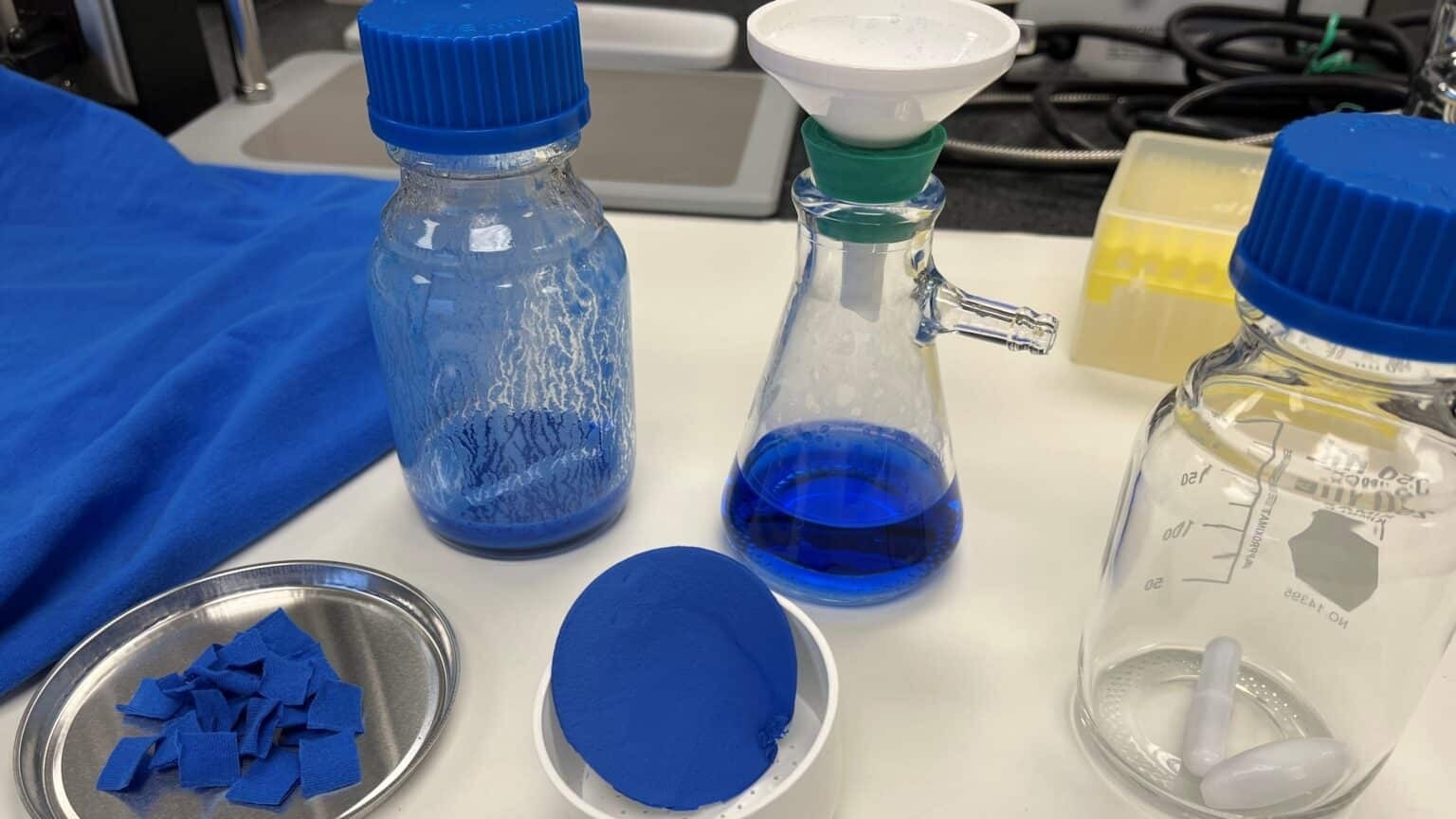

Experts employed a “cocktail” of enzymes in a a little bit acidic answer to chop up cellulose in cotton. Cellulose is the materials that delivers construction to the cell partitions of vegetation. The purpose is to chop up the cellulose so that it “falls out” of the blended woven structure, releasing tiny cotton fiber fragments and glucose powering.

Glucose is a biodegradable by-merchandise of cellulose degradation. The glucose is washed away, and the cotton fiber fragments are filtered, leaving clean up polyester.

This is a delicate process—the therapy is slightly acidic, like employing vinegar. We also ran it at 50 ºC, which is like the temperature of a warm washing machine. It is very promising that we can different the polyester to a clean level. We however have some far more operate to do to characterize the polyester’s homes, but we feel they will be incredibly superior simply because the problems are so moderate. We’re just introducing enzymes that dismiss the polyester.

Sonja Salmon, Examine Corresponding Author and Associate Professor, Textile Engineering, Chemistry and Science, North Carolina Condition College

They likened the degradation of 100{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} cotton fabric to that of cotton and polyester blends and cloth dyed with reactive crimson and blue dyes and dealt with with sturdy push chemicals. The scientists experienced to maximize the time and enzymes to break down the dyed products. They had to use a chemical pre-cure just before introducing the enzymes to materials treated with strong push chemical compounds.

The dye that you pick has a massive effects on the possible degradation of the fabric. Also, we uncovered the largest obstacle so considerably is the wrinkle-resistant finish. The chemistry behind that generates a important block for the enzyme to access the cellulose. Without pre-treating it, we achieved fewer than 10{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} degradation, but after, with two enzyme doses, we were being equipped to entirely degrade it, which was a truly interesting end result.

Jeannie Egan, Analyze Lead Writer and Graduate Student, North Carolina Point out University

The polyester can be recycled, although the slurry of cotton fragments might be useful as an additive for paper or a useful addition to composite materials, according to the scientists. They are also searching into regardless of whether glucose can be employed to generate biofuels.

Salmon notes, “The slurry is produced of residual cotton fragments that resist a quite powerful enzymatic degradation. It has possible worth as a strengthening agent. For the glucose syrup, we’re collaborating on a project to see if we can feed it into an anaerobic digester to make biofuel. We’d be getting squander and turning it into bioenergy, which would be a lot much better than throwing it into a landfill.”

Journal Reference

Egan, J., et al. (2023). Enzymatic textile fiber separation for sustainable waste processing. Methods, Ecosystem and Sustainability. doi.org/10.1016/j.resenv.2023.100118.

Resource: https://www.ncsu.edu/