Some of us may possibly remember the bracing and virtuous come to feel of brushing our teeth or washing our facial area with pastes that seemed to contain a pinch of beach sand or salt didn’t we experience cleaner than clean up?

Nicely, remembering is all that is still left. Individuals toothpastes and pores and skin scrubs did their function with very small beads of plastic, pretty tiny and improperly understood pollutants that are moving by the tons into waterways, soil, animals, food items, and our individual bodies.

The Microbead-Free of charge Waters Act of 2015 banned these small plastic beads from exfoliating scrubs and toothpastes, but that compact motion is just a get at the most affordable-hanging fruit of a international trouble. The environmental threat of microplastics — established mainly by the breakdown of plastic waste — proceeds. In the previous ten years, experts are doing work tougher to capture, measure, and consider the threat of microplastics in locations like Narragansett Bay.

Also, microplastic fibers, a worrisome subset of microplastics, have caught the attention of the textile field, which brings the fibers into remaining, which now needs to obtain strategies to capture and reuse them.

Microplastic is defined as any bits of plastic up to 5 millimeters in measurement. They can be spherical, jagged, or any random shape. They are made by the physical and chemical breakdown of plastic waste, and are discovered in all places on Earth, which include the depths of the oceans, on mountaintops, and in the flesh of animals and breast milk of humans.

It is believed that 44{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} to 50{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of sea birds, sea turtles, otters, and fish have eaten or been entangled in plastic debris. Investigation is seeking at the internal hurt to animals, in particular sea everyday living, that ingest plastic, and to the individuals who eat the animals that have plastic in their bodies. A associated issue is regardless of whether microplastics in the atmosphere act as a vector to soak up and transmit microbes.

Microfibers are defined as very small slivers of product with a 1:3 ratio of width to length. Fibers are “shed,” or thrown off, textiles during the easy actions of using, putting on, and washing them. Besides garments, textiles can incorporate towels and linens, sails and rope, cigarette filters, face masks, and tire tread.

All-natural fibers, this sort of as cotton, linen, wool, and silk, get rid of their fibers, as do polyester, rayon, acetate, and all of the other mixes of artificial materials that originate in an oil nicely.

Experts estimate that about 9 million metric tons of plastic enter the world’s oceans just about every year, according to Past Plastics. About 85{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of microplastic squander in the ecosystem is thought to be microfibers. About 100 million tons of textiles was developed throughout the globe in 2016, reported Martin Bide, retired professor from the Office of Textiles, Style Merchandising and Style and design at the College of Rhode Island. Also in that year, he explained, 62.7{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of the worldwide fiber current market was polyester fibers.

As experts troll the Earth’s waters for microplastics to document and research, persons in the textile, trend, and layout industries are seeking to occur up with methods to accumulate squander plastic and, stated simply just, to melt and then spin the plastic into filaments and fibers that are then employed to weave new cloth.

This operate to retrieve and reuse junk plastic is a variation of the reduce, recycle, refill, and reuse mantra that is aimed now at all sorts of throwaway elements.

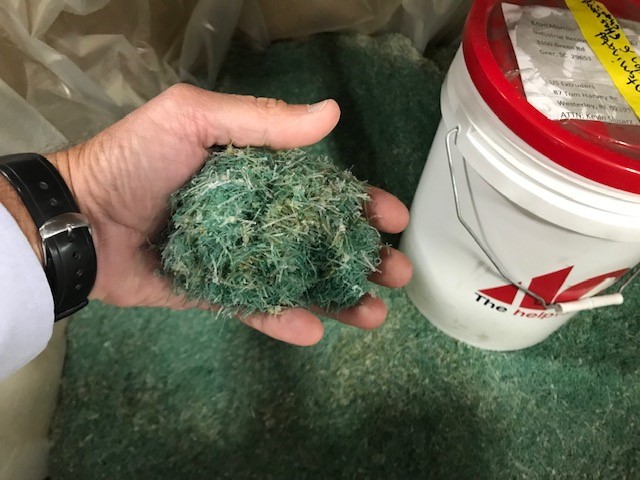

Microfibers, from purely natural components like cotton and petroleum-based mostly components like polyester, enter the natural environment in a dizzying wide variety of approaches, some a lot more apparent than other individuals. Through normal use and motion of outfits, sails, rope, and even cigarette butts, the fibers are lose into the setting. Materials that are tightly woven, with more time fibers, will shed significantly less and more little by little. Short, free-weave fibers get rid of more rapidly. In the entire world of microplastic fibers, 1 of the worst offenders is fleece, a plastic-centered, fluffy fabric.

A person of the key strategies fibers enter the setting is by using the rinse h2o of washing devices. Judith Weis, a retired maritime biology professor from Rutgers College in New Jersey, has analyzed this phenomenon extensively. Wastewater that goes into public sewer units is filtered out of the h2o and into a sludge, a byproduct of remedy. This filtering captures about 90{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of microfibers, but, presented the great volume of these fibers, that even now leaves a large amount of fibers in the treated water, which is inevitably unveiled into waterways.

Additional alarming, sludge may be spread on land, Weis claimed. If spread on farmland, it can enter farm crops by way of their typical uptake of nutrients from the soil. If spread on other lands, it can enter the bodies of bugs, worms, and birds and into the open up air.

“You have just moved the pollution from one particular area to a further,” Weis reported.

Scientists do not know the result of microplastics on animals, individuals, or the ecosystem. “We can only guess,” Weis stated.

At URI, an interdepartmental team of about 50 academics are component of a “laboratory without having walls” that is operating on a variety of interdisciplinary tasks to have an understanding of and reduce this form of pollution. They are sampling the waters of Narragansett Bay, feeding microplastic fibers to oysters and sea urchins, figuring out how to transform plastic squander to fibers at market place-aggressive charges, and devising marketing and advertising approaches to teach the community and to persuade individuals to get fewer and sturdier garments.

In the company realm, Rhode Island Commerce has specified a grant to U.S. Extruders in Westerly to experiment with developing plastic fibers from plastic fishing nets. A trade team, the Rhode Island Textile Innovation Community, is performing with Polaris MEP, an industry advisor, to knit collectively the many players in the condition that could enable create a circular textile economic system in which character-harming plastic waste is captured and reworked into new items.

Far more than one observer has claimed this is elementary function for the Ocean Condition. The Industrial Revolution was launched in America when Englishman Samuel Slater smuggled the ideas for a textile mill out of England and constructed Slater Mill in Pawtucket in 1793. Now, more than 70 textile manufacturers are functioning in Rhode Island, claimed Peter Snyder, vice president for exploration and financial advancement at URI.

Also, the overall health of Narragansett Bay and the wildlife it supports are a massive problem for all Rhode Islanders.

Bide, of URI, claimed the evolution of textiles as today’s new air pollution fret — on scientists’ radar for only about a 10 years — follows the technological and economic trends at get the job done in The us throughout the a long time. Up to the 1900s, textiles ended up built of normal fibers this kind of as cotton and wool. The early 20th century introduced the creation of artificial nitrogen fertilizer, adopted by nylon as the initially oil-dependent synthetic fiber, then followed by polyester and other synthetic merchandise.

The sequence carries on as a result of the 20th century with cheap oil for the creation of polyester, economical machinery for producing low cost materials, plenty of clothes sewn by small-wage personnel in the 3rd Globe, primary to less expensive dresses and a quickly-vogue market that flogs people into a lot more buying.

“Instead of purchase, hold, mend, it became acquire, throw absent, and purchase additional,” Bide stated.

The populace of the United States has quadrupled since 1900, Bide stated, although textile use has absent up 30-fold. At existing, the international intake of apparel is additional than 30 lbs . for every person every year. In the United States, the figure is much more than 100 pounds. Most of it is polyester.

Assistant professor Izabel Ciesielska-Wrobel of the textiles department at URI is working on a design of a remedy less than a job titled “Conversion of Plastic Squander into Economically Viable Filaments and Fibers.” The venture bought underway ahead of she joined URI, while she was doing the job for Luna Improvements of Virginia. Income from the U.S. Division of Electricity bought the challenge rolling.

At URI, Ciesielska-Wrobel’s task acquired a $186,000 micro compounder. The equipment starts with waste plastic, then melts it and extrudes a extremely thin plastic filament. (Extrude is to develop a product or service by pushing a thing through an opening. Envision producing do-it-yourself pasta, or the common Participate in-Doh toy in which a load of Perform-Doh in a hopper is pushed by a panel of minimize-out shapes.)

Of system, the method is not that uncomplicated, partly since of the selection of polymers and additives in any plastic. “Some products are not admissible” into the course of action, Ciesielska-Wrobel reported, “so you have to use a lot of chemistry to make them admissible.”

“This device offers a lot of opportunities,” she explained. “Also, we are incorporating options to the products to make them additional appealing to probable shoppers.” In simple fact, she features some of her monofilament product to use in 3D printing.

Ciesielska-Wrobel reported there is a large amount of fascination in the small business environment in changing squander plastic to usable filaments and fibers. She has labored to some degree with OceanWorks, a California-dependent firm with an business office in Boston, which, she said, collects trash plastic from all in excess of the earth, and then separates and processes it into usable plastic pellets. She stated it is tricky to get in touch with OceanWorks in modern months, implying to her that its enterprise is booming.

“My purpose is to promote this strategy everywhere you go and to consider to use it in every single possible way that I can,” she explained.

Equivalent experimentation — by way of a job identified as “Fishing for Solutions” — is now likely on at U.S. Extruders, with aid from the $43,000 Commerce grant. The corporation builds extruding devices that, in turn, are made use of by other manufacturers to extrude merchandise, this kind of as health-related tubing. Business enterprise advancement officer John Riendeau explained the company’s operator, Dan Schilke, was disturbed by the very low degree of recycling in the United States and resolved to operate on a resolution.

The firm resolved, Riendeau claimed, “to do a little consultant case in point of recycling a thing that has not been recycling in the past” — that is, fishing nets, which are primarily plastic apart from for some detachable things of metal and rubber.

“The strategy was to acquire an end-of-lifestyle product and turn it into part of the round economic system,” he additional.

U.S. Extruders obtains scraps of fishing nets from Remarkable Trawl and Trawlworks, web brands in Narragansett, that are byproducts of creation. The procedure features separating the steel and rubber, cleansing the nets, shredding and granulating the plastic, and developing plastic pellets to be bought to a range of producers of all forms of items. The very important concern, Riendeau mentioned, is whether the charge of developing the recycled plastic can compete with the cost of generating and buying virgin plastic.

Study of the quantity and impact of microplastics in the surroundings is somewhat young, and experts, including marine biologists, are doing the job with exclusive logistical challenges.

Andrew Davies and Coleen Suckling are associate and assistant professors, respectively, at URI, and they are finding out plastic particles in Narragansett Bay as a result of the Ocean Condition Initiative for Maritime Plastics.

A 2020 Rhode Island Sea Grant challenge has authorized them to do surface area trawling of the bay. The work is demanding, said Davies, simply because of the several unique types of particles in the drinking water, together with plastic, that create a “noisy matrix” that is hard to form by means of. Also, different plastics have diverse densities and may possibly behave in another way in water. At this early stage, their analysis has yielded several conclusions.

Experts also are studying the presence of microplastics on the floor of the bay, in sediments, which ultimately seize an estimated 70{5e37bb13eee9fcae577c356a6edbd948fa817adb745f8ff03ff00bd2962a045d} of all microplastics that enter waterways, according to Kay Ho, study scientist for the Environmental Protection Agency who is performing on sediment investigate in Narragansett Bay. Ho explained marine experts obtain microplastic sediments “everywhere we glance,” but the consequences of this air pollution are even now typically mysterious.

Weis, of Rutgers University, said the science of gathering and analyzing microplastics and microfibers in the surroundings is fraught with troubles and inconsistencies. In a paper Weis co-wrote with Francesca De Falco, a member of the School of Organic and Maritime Sciences at the College of Plymouth in England, Weis uncovered some researchers collect samples with varieties of nets that allow lengthy thin fibers to escape, ensuing in a serious undercount of fibers. “Grab samples” of whole drinking water may get a far more accurate rely, but they can not be usefully in comparison to samples captured in nets. Laboratory studies that use obtained samples of microplastic beads mismatch, in many approaches, the conditions in the organic environment.

Some steps that Weis and De Falco advise to seize microplastic fibers from just the constrained globe of clothes would demand a good deal of consumer schooling and habits change. These would incorporate buying apparel with tight weave washing clothes in whole hundreds, if possible in a entrance-loading machine (to lessen agitation) utilizing less detergent drying apparel on a line instead of in a outfits dryer. Washing devices with crafted-in filters that can seize microfibers do exist, and, in actuality, will be mandated in all new washing equipment marketed in France in the upcoming number of many years. Meanwhile, these fine-grain filters can be obtained and retrofitted onto existing washing devices, Weis explained. Just one merchandise is the Lint LUV-R.

Karl Aspelund, associate professor and chairman of the Department of Textiles, Fashion Merchandising and Layout at URI, emphasised that all the initiatives explained listed here — from combing the bay ground to spinning recycled plastic into yarns — are matters that professionals by now know how to do.

“We don’t have to invent everything to make all of this materialize,” Aspelund stated. “This is not one thing we have to occur up with.” The activity, which URI is encouraging to operate on, is “getting folks to begin working together.”